Polyurethane bushings offer superior strength and flexibility for automotive applications. They absorb shock, reduce noise, enhance installation, and provide versatility for various vehicle models. OEM bushings ensure seamless integration and optimal performance, while aftermarket options cater to customization. Proper installation, maintenance including regular inspections and lubrication, and timely replacement extend their lifespan.

“Polyurethane bushings are revolutionizing automotive components, offering enhanced performance and longevity. This article delves into the world of these innovative bushing materials, exploring their unique properties and benefits. We’ll dissect the difference between OEM and aftermarket polyurethane bushings, highlighting compatibility and performance considerations.

Additionally, practical installation and maintenance tips will ensure optimal bushing lifespan, providing a reliable solution for vehicle owners. Discover why polyurethane bushings are a game-changer in automotive technology.”

- Understanding Polyurethane Bushings: Material and Benefits

- OEM vs Aftermarket: Compatibility and Performance

- Installation and Maintenance Tips for Longevity

Understanding Polyurethane Bushings: Material and Benefits

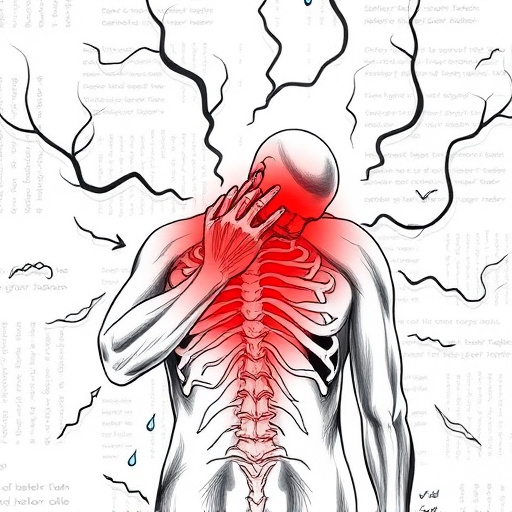

Polyurethane bushings are an innovative solution in automotive components, offering both strength and flexibility that traditional materials can’t match. Crafted from high-quality polyurethane, these bushings set a new standard for durability and performance, ensuring longevity even under extreme conditions. The material’s unique properties allow it to absorb and dissipate shock and vibrations effectively, which translates into smoother rides and reduced noise levels in vehicles.

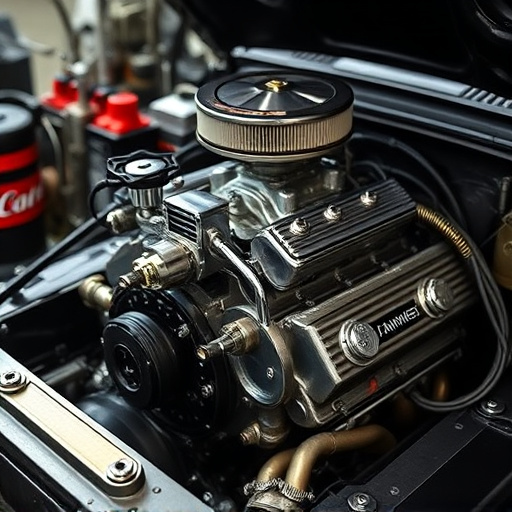

Beyond their structural advantages, polyurethane bushings provide significant improvements in installation and maintenance. They are known for their compatibility with both OEM (Original Equipment Manufacturer) and aftermarket components, ensuring seamless fitment and easier replacement of worn-out parts, such as those found in exhaust systems, including performance exhausts and muffler tips. This versatility makes them a popular choice among car enthusiasts looking to enhance their vehicles’ overall performance and stability without compromising comfort or safety.

OEM vs Aftermarket: Compatibility and Performance

When it comes to compatibility and performance, understanding the difference between OEM (Original Equipment Manufacturer) and aftermarket polyurethane bushings is key. OEM bushings are designed specifically for a vehicle’s original components, ensuring seamless integration and optimal functioning. They are crafted to precise specifications, guaranteeing a perfect fit with the vehicle’s existing parts, such as intake components, brake rotors, or suspension kits. This precision leads to enhanced stability, reduced noise, and improved overall handling.

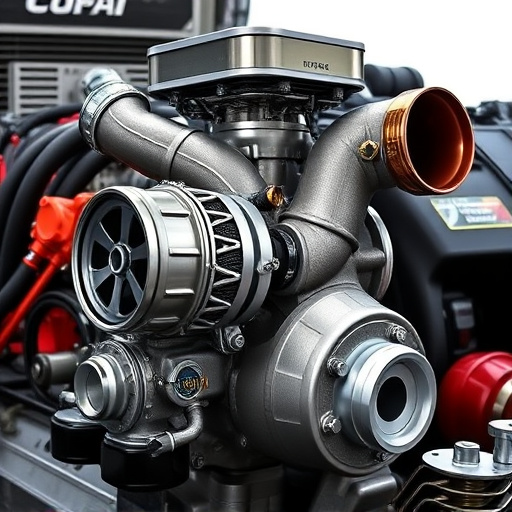

Aftermarket polyurethane bushings, on the other hand, offer a broader range of options for various vehicle models and applications. While they may not always match the exact dimensions and specifications of OEM parts, they are engineered to provide comparable performance. Aftermarket bushings can be tailored to meet specific needs, whether it’s enhancing ride quality, reducing vibration, or allowing for easier customization with custom suspension kits. This versatility makes them a popular choice among car enthusiasts seeking to fine-tune their vehicle’s performance and aesthetics.

Installation and Maintenance Tips for Longevity

Proper installation and regular maintenance are key to maximizing the lifespan of polyurethane bushings, ensuring they provide their intended benefits for years to come. When installing these bushings, it’s crucial to follow manufacturer guidelines carefully. Use the appropriate tools to avoid damage during the process. Ensure all parts are clean and free from debris before assembly. A secure fit is essential; tight connections prevent unwanted movement that could lead to premature wear.

Maintenance involves regular inspection for signs of wear or damage. Polyurethane bushings can take a beating, especially in vehicles with demanding suspension components, exhaust systems, or exhaust tips. Keep an eye out for cracks, brittle material, or excessive play. Lubrication might be required under certain circumstances, but check the product specifications first as not all polyurethane bushing designs benefit from lubrication. Regular maintenance includes tightening connections periodically to account for natural wear and tear.

Polyurethane bushings offer a compelling solution for both original equipment manufacturer (OEM) and aftermarket components, providing enhanced durability and performance. By understanding the material’s benefits and compatibility considerations, as well as proper installation and maintenance practices, vehicle owners can ensure optimal longevity and seamless integration of these innovative parts. Incorporating polyurethane bushings into your vehicle’s suspension system can lead to improved handling, reduced noise, and increased safety—making them a smart choice for those seeking top-notch automotive upgrades.