Recognize signs of worn polyurethane bushings like unusual noises, tire wear, vehicle pulling, and visible damage. Replace them for optimal performance, safety, and reduced maintenance costs. Polyurethane bushings offer superior durability, handling, and stability compared to rubber alternatives. DIY installation involves removing old bushings, cleaning surfaces, inserting new ones, and testing alignment for enhanced suspension.

Are your vehicle’s suspension components shouting for help? Worn-out bushings are often overlooked yet can significantly impact handling and comfort. Learn to identify common signs of deterioration, such as increased noise or irregular tire wear. Discover the superior performance of polyurethane bushings, offering enhanced durability, reduced vibration, and improved control. This step-by-step guide will walk you through the installation process, ensuring a smooth upgrade for better driving dynamics.

- Recognize Common Signs of Worn Bushings

- Understanding Polyurethane Bushing Advantages

- Step-by-Step Guide to Installation

Recognize Common Signs of Worn Bushings

Recognize Common Signs of Worn Bushings

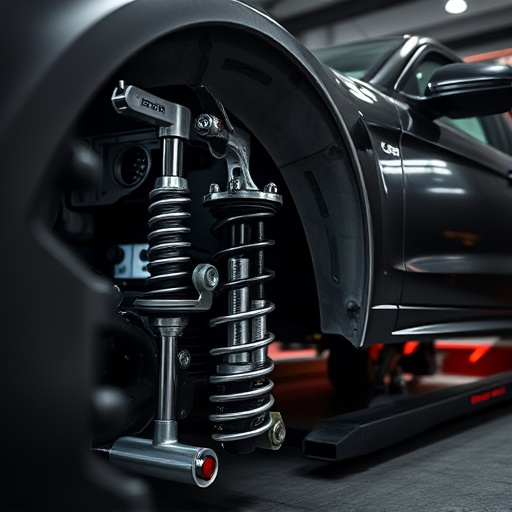

One of the first signs that your vehicle’s bushings are worn out is unusual noises coming from your suspension or steering system. This could range from clunking and banging sounds to a squeaking or grinding noise, particularly when navigating turns or over bumps. Another telltale sign is excessive tire wear, as worn bushings can cause tires to wear down unevenly due to misaligned wheels or uneven weight distribution. Additionally, if you notice your vehicle pulling to one side while driving straight or experiencing a noticeable wobble in the steering wheel, these are strong indications that your bushings may be shot.

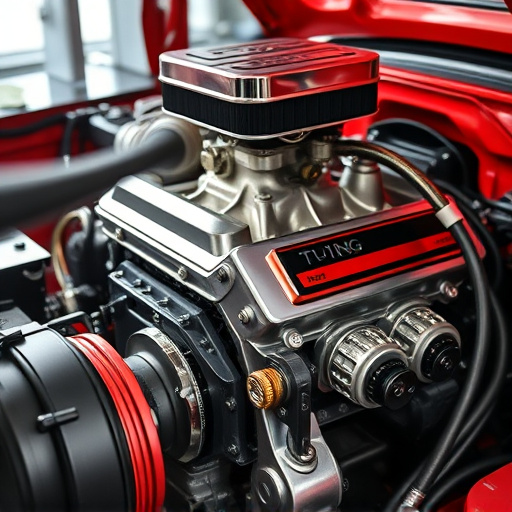

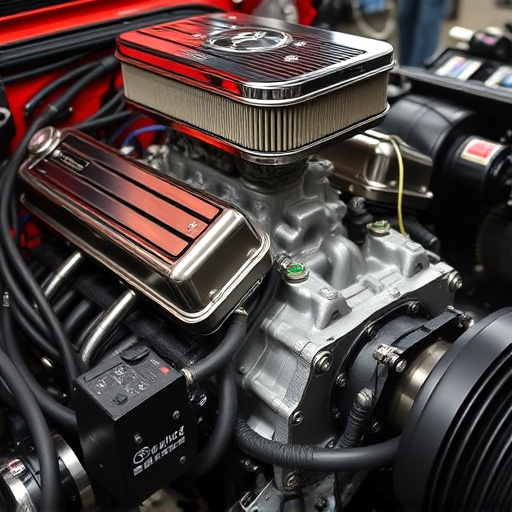

Examine your vehicle’s exhaust tips and performance air filters for any visible damage or debris buildup. Worn bushings can contribute to components becoming loose, allowing them to accumulate dust, dirt, and even small rocks. Regularly inspect these areas for signs of wear and tear, as this could be another clue that your polyurethane bushings need replacing. Moreover, if you’re noticing a decrease in the overall performance exhaust or a loss of power, it might be worth considering the condition of your bushings alongside other potential issues like clogged filters or damaged mufflers.

Understanding Polyurethane Bushing Advantages

Polyurethane bushings offer a range of advantages over their rubber counterparts, making them an increasingly popular choice for vehicle upgrades, especially in high-performance parts and performance exhaust systems. One of the key benefits is their superior durability and resistance to wear and tear. Polyurethane is less susceptible to cracking and breaking down over time, ensuring longer lifespans even under extreme conditions. This longevity translates into reduced maintenance costs as you won’t need to replace them as frequently.

Additionally, polyurethane bushings provide better control and stability due to their rigid nature. They can enhance the overall handling and response of your vehicle, particularly when paired with high-performance brake pads. The material’s ability to maintain its shape under compression and return to its original form makes it an ideal choice for applications where smooth and precise movement is essential. This feature is especially valuable in enhancing cornering capabilities and improving overall driving dynamics.

Step-by-Step Guide to Installation

Upgrade your vehicle’s suspension with a simple do-it-yourself project and say goodbye to worn-out bushings. Here’s a step-by-step guide to installing polyurethane bushings, offering superior durability and performance compared to traditional rubber alternatives. Begin by identifying the bushings in need of replacement – these are typically located near the wheels, connecting the suspension components to the chassis. Using a socket wrench or similar tool, carefully remove the old bushings from their sockets without damaging surrounding parts.

Next, clean the mounting surfaces thoroughly with a degreaser to ensure optimal adhesion for your new polyurethane bushings. Insert the new bushings into the sockets, ensuring they are properly seated and secure. For added stability, consider using thread locker or lock nuts as recommended by the manufacturer. Once installed, test fit other components like air filter kits, muffler tips, or air intake systems to ensure proper alignment and clearance, completing your upgraded suspension setup with enhanced stability and reduced noise levels.

Identifying worn-out bushings and upgrading to polyurethane is a smart move for maintaining vehicle performance. By understanding common signs of wear and the advantages of polyurethane bushings, you can make an informed decision that enhances handling, reduces noise, and prolongs the life of your suspension components. Following a simple step-by-step guide ensures a successful upgrade, providing long-lasting benefits for a smoother ride.