Polyurethane bushings offer superior stability and durability compared to traditional rubber or metal parts, enhancing wheel alignment, reducing vibrations, improving handling, and protecting critical suspension components. They adapt to road surfaces and vehicle movement, ensuring optimal contact in cornering and braking, benefiting high-performance vehicles. Beyond automotive, polyurethane bushings are transforming industries with their exceptional wear resistance, shock absorption, and noise reduction, from construction to performance brakes.

Polyurethane bushings are transforming wheel alignment technology, offering unparalleled stability and durability. This article delves into the world of these innovative components, exploring their construction with advanced materials and the significant advantages they bring to various industries. From enhancing precision in automotive alignments to providing shock absorption in heavy machinery, polyurethane bushings ensure optimal performance and prolonged equipment lifespan. Discover how this versatile material is revolutionizing stability across diverse applications.

- Understanding Polyurethane Bushings: Materials and Benefits

- How Polyurethane Bushings Enhance Wheel Alignment

- Applications: Industries Using Polyurethane Bushings for Stability

Understanding Polyurethane Bushings: Materials and Benefits

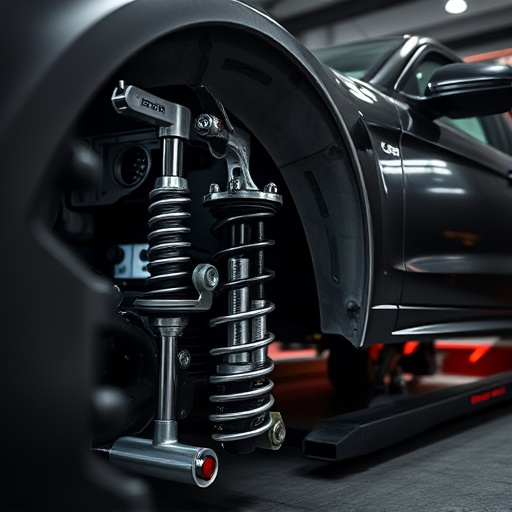

Polyurethane bushings are engineered to bring superior stability and performance to a vehicle’s wheel alignment. Unlike traditional rubber bushings, which can compress and deform over time, polyurethane offers exceptional durability and rigidity. This material is known for its high resistance to wear and tear, ensuring that critical suspension components maintain their original shape and position even under extreme conditions.

The benefits of using polyurethane bushings extend beyond mere structural integrity. They also contribute to enhanced vehicle performance by reducing energy loss due to excessive flexibility in the suspension system. This is particularly advantageous when it comes to handling precise control during cornering, braking, and acceleration. Additionally, their robust construction minimizes noise vibrations, improving ride comfort while also protecting sensitive intake and brake components from damage caused by excessive movement.

How Polyurethane Bushings Enhance Wheel Alignment

Polyurethane bushings significantly enhance wheel alignment stability by providing superior support and flexibility compared to traditional rubber or metal parts. Their unique composition allows them to absorb and distribute forces more efficiently, reducing the risk of damage to critical suspension components like control arms and steering racks. This enhanced durability ensures that your vehicle’s wheel alignment remains precise for longer periods, leading to improved handling and safety.

Moreover, polyurethane bushings offer better compliance under various driving conditions, including cornering and braking maneuvers. Unlike rigid metal parts, they can conform to changes in road surfaces and vehicle movement, maintaining optimal contact between suspension parts. This adaptability is particularly beneficial for vehicles with high-performance brake components or intake systems like air intake components, ensuring consistent performance regardless of the terrain or driving style.

Applications: Industries Using Polyurethane Bushings for Stability

Polyurethane bushings have found their way into various industries, revolutionizing stability and performance across different sectors. From automotive to heavy machinery, these versatile components are making waves. In the automotive sector, they’re not just enhancing wheel alignment; they’re also being used in high-performance vehicles with performance air filters and exhaust tips to mitigate vibrations and improve handling. This is particularly beneficial for off-road vehicles and sports cars where precision steering and stability at high speeds are paramount.

Moreover, industries that rely on robust machinery, such as construction equipment and manufacturing plants, are leveraging polyurethane bushings for their exceptional durability and resistance to wear and tear. Unlike traditional bushing materials, polyurethane offers a unique combination of flexibility and strength, effectively managing shock absorption and reducing noise levels in mechanical systems. Even with performance brakes, which demand superior heat resistance, polyurethane bushings prove their mettle, ensuring consistent stability under extreme conditions.

Polyurethane bushings have emerged as a game-changer in various industries, offering unparalleled stability and performance. By understanding their unique material properties and how they enhance wheel alignment, professionals can ensure optimal vehicle dynamics and improved safety standards. The versatility of polyurethane bushings makes them an essential component for navigating diverse applications, from automotive to industrial machinery, ultimately revolutionizing the way we maintain stability and precision.