Polyurethane bushings, made from durable synthetic polymer, outperform traditional rubber or plastic parts in shock absorption and vibration reduction, especially in suspension kits and muffler tips. They resist chemicals, UV rays, and extreme temperatures, ensuring long-lasting performance for critical suspension parts. The right polyurethane bushings for exhaust mufflers or air intakes enhance vehicle durability and safety. Installation is easy, but regular upkeep like cleaning and lubrication is crucial for maximum lifespan.

“Discover the versatility and durability of polyurethane bushings, essential components for daily and track use applications. This comprehensive guide explores the polyurethane bushings you need to know, from understanding materials and unmatched advantages to ensuring optimal performance and longevity. Learn how to choose the right bushing for your specific needs and master installation, maintenance tips, and more. Elevate your application with these game-changing polyurethane bushings.”

- Understanding Polyurethane Bushings: Materials and Advantages

- Choosing the Right Bushing for Your Application

- Installation, Maintenance, and Longevity of Polyurethane Bushings

Understanding Polyurethane Bushings: Materials and Advantages

Polyurethane bushings are a type of automotive component that has gained significant popularity among car enthusiasts and mechanics alike. These bushings are primarily made from polyurethane, a versatile synthetic polymer known for its exceptional durability and flexibility. When compared to traditional rubber or plastic components, polyurethane offers superior resistance to wear and tear, making it ideal for handling the rigors of daily driving and track use.

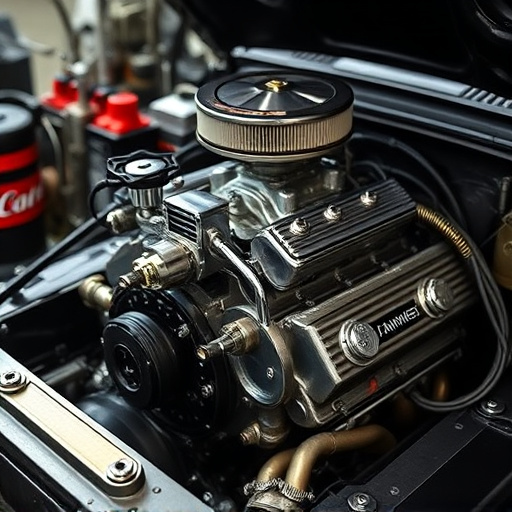

The advantages of using polyurethane bushings are numerous. First and foremost, their ability to absorb shock and reduce vibration makes them a great alternative to stock rubber bushings, particularly in suspension kits or muffler tips. This feature not only enhances ride comfort but also contributes to improved vehicle handling. Additionally, polyurethane is highly resistant to chemicals, UV rays, and extreme temperatures, ensuring that the bushings maintain their integrity over time, even under demanding conditions. This longevity translates into reduced maintenance costs and increased reliability for your vehicle’s suspension components, including critical parts like control arms and strut mounts.

Choosing the Right Bushing for Your Application

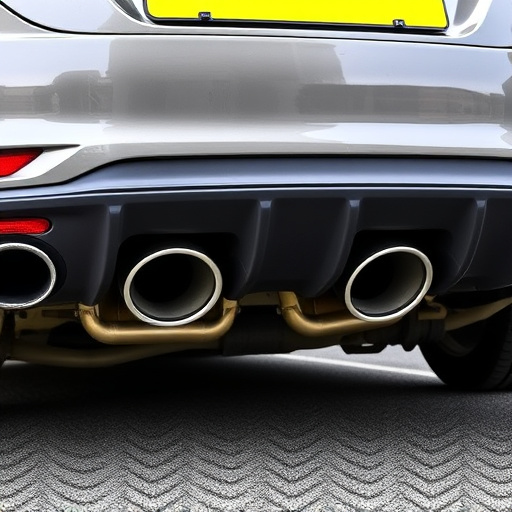

When selecting polyurethane bushings for your vehicle’s exhaust mufflers or air intake systems, understanding your specific application is key. Polyurethane bushings are known for their exceptional durability and versatility, making them suitable for a wide range of uses. For instance, in the case of exhaust tips and mufflers, these bushings can effectively manage the constant vibrations and movements caused by track use, ensuring a secure fit that withstands the rigours of daily driving and extreme conditions.

The right polyurethane bushing will offer a balance between flexibility and rigidity, allowing for smooth operation while providing enough support to prevent excessive wear and tear. Consider factors like the bushings’ load capacity, hardness, and material composition to match it perfectly with your vehicle’s requirements. This ensures optimal performance and longevity for components like exhaust systems, enhancing overall driving experience and safety.

Installation, Maintenance, and Longevity of Polyurethane Bushings

Polyurethane bushings are designed for ease of installation, making them a popular choice among car enthusiasts and mechanics alike. They typically replace rubber or plastic components in various automotive systems, such as muffler tips, air intake systems, and performance brakes. The process involves removing the old bushing and inserting the new polyurethane one, often with simple tools and without the need for complex procedures. This accessibility contributes to their widespread adoption, ensuring a straightforward maintenance routine.

Regular upkeep is key to maximizing the lifespan of these bushings. Basic cleaning and visual inspections can help identify any signs of wear or damage early on. For performance brakes, periodic lubricating the bushings according to manufacturer recommendations can further extend their service life. Additionally, keeping air intake systems clean ensures optimal airflow, preventing unnecessary strain on the bushing components. With proper care, polyurethane bushings can endure daily use and track activities, providing reliable performance for extended periods.

Polyurethane bushings offer a remarkable balance of durability, flexibility, and cost-effectiveness, making them an excellent choice for various applications. By understanding their materials, advantages, and selecting the right fit for your needs, you can ensure optimal performance and longevity in both daily use and demanding track conditions. Proper installation, regular maintenance, and awareness of potential wear indicators will further contribute to the successful integration of polyurethane bushings into your machinery or vehicles.