Polyurethane bushings are advanced suspension components for modern vehicles, offering improved performance and control compared to traditional rubber or plastic alternatives. They provide superior durability, load distribution, and shape retention, enabling optimal shock absorption even under heavy loads. Ideal for high-performance vehicles with exhausts or intakes, these bushings enhance handling, ride quality, and reduce maintenance needs. Choosing the right polyurethane bushings based on environmental conditions, comfort preferences, and automotive part requirements ensures maximum benefits across various applications.

Polyurethane bushing technology is revolutionizing suspension systems, offering unparalleled precision and durability. This article delves into the fundamentals of polyurethane bushings, highlighting their unique advantages for long-term performance. From improved load distribution to enhanced noise reduction, these bushings are a game-changer in vehicle dynamics. We’ll explore how to select the ideal polyurethane bushing for specific applications, ensuring optimal suspension precision and vehicle handling.

- Understanding Polyurethane Bushings: The Basics

- Advantages of Polyurethane Bushings for Long-Term Suspension Precision

- Choosing the Right Polyurethane Bushing for Your Application

Understanding Polyurethane Bushings: The Basics

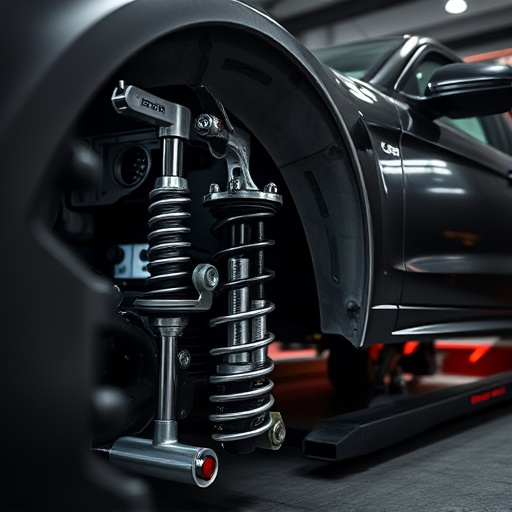

Polyurethane bushings are an essential component in automotive suspension systems, offering a range of benefits that contribute to improved vehicle performance and handling. These bushings are designed to connect various parts of the suspension, such as control arms, struts, and shock absorbers, providing a flexible yet durable interface. Crafted from high-performance polyurethane materials, they offer superior strength and flexibility compared to traditional rubber or plastic components.

The versatility of polyurethane allows it to withstand extreme temperatures, making it ideal for vehicles that demand high-performance parts, especially in demanding driving conditions. This material is also known for its resilience against wear and tear, ensuring the longevity of exhaust tips and muffler tips by maintaining their shape over extended periods. Unlike conventional bushings, polyurethane variants do not stiffen over time, preserving the suspension’s precision and ensuring a smooth ride even under heavy loads or during sharp turns.

Advantages of Polyurethane Bushings for Long-Term Suspension Precision

Polyurethane bushings offer several key advantages when it comes to maintaining long-term suspension precision. Firstly, their superior durability ensures they withstand the rigours of daily driving and extreme conditions better than traditional bushings, minimizing wear and tear over time. This longevity is particularly beneficial for vehicles equipped with performance-oriented components like cat back exhausts or cold air intakes, which can place additional stress on suspension systems.

Moreover, polyurethane provides exceptional load distribution and shock absorption. Unlike some rubber compounds, it retains its shape even under heavy loads, preventing unwanted compliance that could negatively impact handling and ride quality. This characteristic is especially valuable for vehicles with sporty suspensions and intake components designed to optimize engine performance, ensuring the driver enjoys precise control and a smooth ride throughout their ownership experience.

Choosing the Right Polyurethane Bushing for Your Application

Selecting the optimal polyurethane bushing for your specific application requires careful consideration. These bushings, known for their exceptional durability and flexibility, are integral to various automotive components like muffler tips and brake systems. When choosing, factor in the load capacity needed, environmental conditions, and desired level of vibration isolation. High-performance vehicles often demand bushings that can withstand extreme forces and temperatures, while more standard applications may require a simpler design.

Polyurethane offers an advantage over traditional materials by providing both compliance for comfort and rigidity for stability. For instance, in high performance parts, precise suspension alignment is crucial. The right polyurethane bushing ensures component longevity, improves handling dynamics, and delivers a smoother ride. When selecting, consider the specific requirements of each part—from engine mounts to control arm bushings—to achieve optimal performance and reduce maintenance needs over time.

Polyurethane bushings offer a superior solution for maintaining long-term suspension precision in various applications. Their unique properties ensure enhanced durability, reduced wear and tear, and consistent performance, making them an excellent choice for automotive, industrial, and heavy machinery sectors. By carefully considering factors like load capacity, temperature ranges, and environmental conditions, you can select the perfect polyurethane bushing to elevate your system’s overall efficiency and reliability.