Polyurethane bushings are high-performance automotive components offering durability, shock absorption, and noise reduction across various applications. When switching from OEM to aftermarket parts, careful engineering is required to maintain compatibility and vehicle handling. Choosing the right polyurethane bushing design for specific vehicle components like exhausts or brakes ensures accurate alignment, longevity, and optimal performance. Proper installation techniques are crucial for maximizing benefits, preventing damage, and considering unique mounting needs of aftermarket components.

Polyurethane bushings are essential components in automotive suspension systems, offering superior performance over traditional materials. This article delves into the world of polyurethane bushings, exploring their materials and benefits that set them apart. We analyze fitment challenges between OEM and aftermarket components, providing valuable insights for enthusiasts. Learn selection and installation tips to ensure optimal performance and extend the lifespan of your vehicle’s suspension. Discover why these bushings are a game-changer for a smoother, more controlled ride.

- Understanding Polyurethane Bushings: Materials and Benefits

- Fitment Challenges: OEM vs Aftermarket Components

- Selection and Installation Tips for Optimal Performance

Understanding Polyurethane Bushings: Materials and Benefits

Polyurethane bushings are an innovative solution in automotive engineering, offering a range of benefits for both original equipment manufacturer (OEM) and aftermarket components. Crafted from high-performance polyurethane materials, these bushings set a new standard in terms of durability and performance. The primary advantage lies in their ability to withstand extreme conditions, including varying temperatures and constant mechanical stress, without compromising integrity.

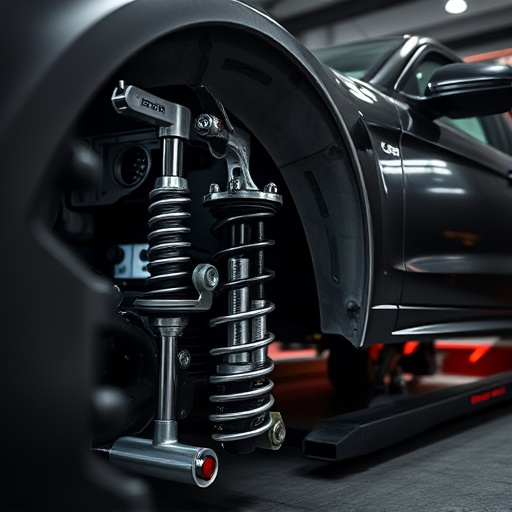

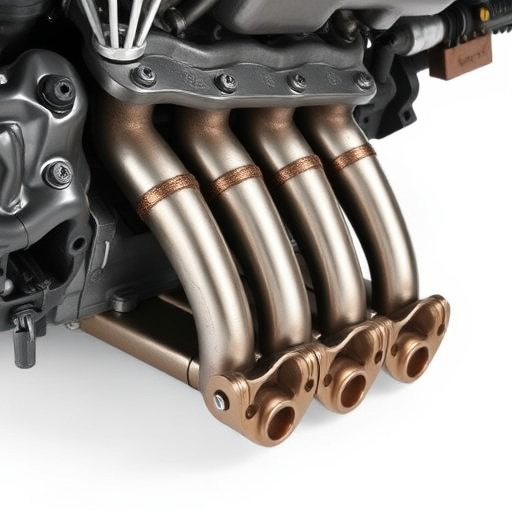

This versatility makes polyurethane bushings ideal for various applications, from suspension components to air intake systems and even brake rotors. Their flexibility allows for superior shock absorption and noise reduction, ensuring a smoother ride and enhancing overall vehicle performance. The material’s resilience against wear and tear promotes longer component lifespans, making it a cost-effective choice for both manufacturers and consumers.

Fitment Challenges: OEM vs Aftermarket Components

When it comes to fitting polyurethane bushings, whether you’re working with original equipment manufacturer (OEM) or aftermarket components, challenges arise due to design variations. OEM parts are often meticulously engineered to fit perfectly within a vehicle’s framework, ensuring optimal performance and safety. However, aftermarket components may not adhere to these precise standards, leading to potential misalignments. Aftermarket manufacturers sometimes focus on cost-effectiveness and quick production, resulting in bushings that might not accurately replicate the OEM fitment.

This discrepancy can be problematic, especially when dealing with critical components like suspension systems or performance brakes. Aftermarket polyurethane bushings designed to replace OEM parts may not provide the same level of stability and precision, potentially affecting vehicle handling and braking efficiency. On the other hand, customizing aftermarket bushings to match OEM specifications requires careful engineering and measurement, ensuring compatibility without compromising performance or safety.

Selection and Installation Tips for Optimal Performance

When selecting polyurethane bushings for your vehicle, it’s crucial to consider both OEM and aftermarket compatibility for optimal results. High-performance parts like exhaust tips and brake rotors often require specific bushing designs to ensure proper alignment and durability. Look for bushings that offer a balance between flexibility and stiffness to accommodate the unique movements of these components.

During installation, precision is key. Ensure all parts are properly aligned and fitted securely. Using appropriate tools and following manufacturer guidelines can prevent damage and maximize the performance benefits of polyurethane bushings. This includes considering thread sizes, bolt patterns, and any special mounting requirements, especially when replacing or upgrading components like exhaust systems or braking components.

Polyurethane bushings offer a compelling solution for both original equipment manufacturer (OEM) and aftermarket components, bridging fitment gaps and enhancing performance. By understanding their unique materials and benefits, as well as following selection and installation tips, you can ensure optimal results. Incorporating polyurethane bushings into your vehicle’s setup not only improves ride quality but also contributes to a smoother, more efficient driving experience.