Polyurethane bushings are superior substitutes for traditional rubber parts, thanks to their blend of flexible polymer and rigid synthetic materials. They offer enhanced shock absorption, noise reduction, and structural integrity under extreme pressure, making them ideal for suspension systems (e.g., coilover kits), air intake systems, and exhaust components in cars, as well as industrial machinery where robustness, chemical resistance, and cost-effectiveness are essential. Their durability reduces replacement needs, while their versatility caters to diverse industries seeking reliable performance and stability under demanding conditions.

Discover the remarkable world of polyurethane bushings, a versatile material revolutionizing industries. This article explores their unique properties and advantages over traditional bearings. We delve into why compression and deformation resistance is critical for reliable performance, ensuring longevity in demanding applications. From automotive to manufacturing, learn how these polyurethane bushings are transforming systems, offering enhanced stability and durability. Uncover the diverse benefits that make them an indispensable choice across various sectors.

- Understanding Polyurethane Bushings: Properties and Advantages

- Why Compression and Deformation Resistance Matters

- Applications and Benefits in Various Industries

Understanding Polyurethane Bushings: Properties and Advantages

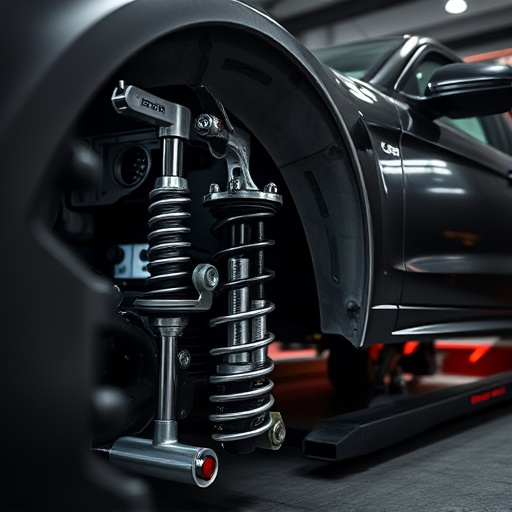

Polyurethane bushings are engineered to withstand extreme pressure and stress without compromising their structural integrity. Unlike traditional rubber bushings, they offer enhanced durability and resistance to both compression and deformation. This makes them an excellent choice for various applications, including but not limited to suspension kits and coilover kits, where robustness is paramount.

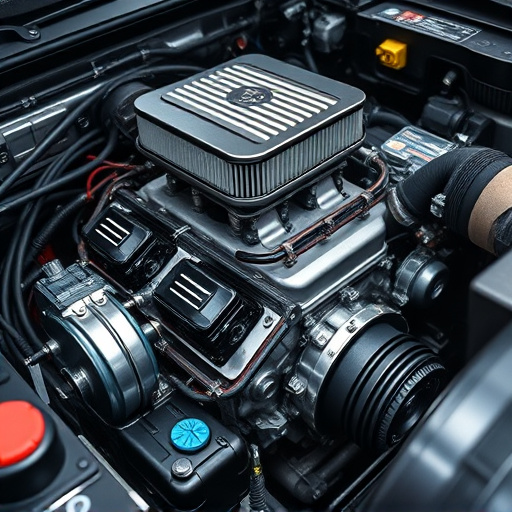

Their unique properties stem from the chemical composition of polyurethane, which combines the flexibility of polymers with the rigidity of synthetic materials. This blend results in bushings that maintain their shape under heavy loads, providing superior shock absorption and noise reduction. Additionally, polyurethane bushings are compatible with air intake systems, further expanding their utility across diverse industries.

Why Compression and Deformation Resistance Matters

Polyurethane bushings designed to resist compression and deformation are essential components for any vehicle looking to maintain optimal performance and handling. These bushings play a critical role in keeping suspension components aligned, ensuring smooth movement and enhancing overall stability. In the context of coilover kits or even when installing a cat-back exhaust system, the ability to withstand pressure and maintain shape is paramount.

When subjected to constant compression and deformation, typical bushings can degrade quickly, leading to loose suspensions and potentially compromising vehicle control. High-quality polyurethane bushings, however, offer enhanced durability, reducing the need for frequent replacements. This feature not only saves costs but also guarantees consistent vehicle performance, making them a smart upgrade for any car enthusiast looking to maximise their ride’s potential.

Applications and Benefits in Various Industries

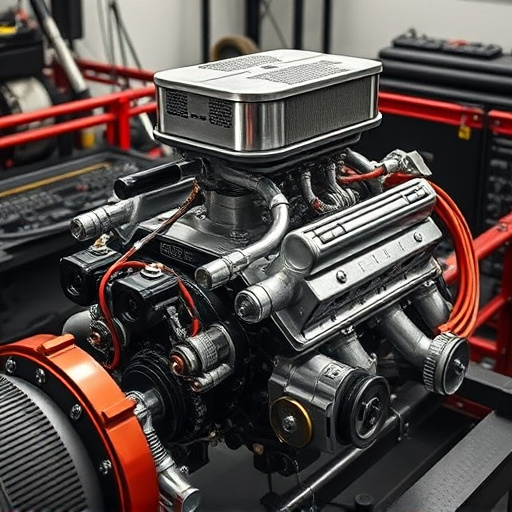

Polyurethane bushings offer a versatile solution for various industries, catering to unique applications where resistance to compression and deformation is paramount. Their superior flexibility and durability make them indispensable in automotive components such as air intake systems and exhaust tips, ensuring optimal performance and longevity. The ability to withstand extreme conditions without compromising structural integrity is particularly valuable in these high-stress environments.

Beyond the automotive sector, polyurethane bushings find utility in industrial machinery, where they serve as vibration isolators and load-bearing supports. Their lightweight nature and resistance to chemicals make them ideal for maintaining equipment efficiency and extending service life. In applications like manufacturing plants, where vibrations can cause significant wear and tear, these bushings provide a cost-effective and efficient solution, enhancing overall operational stability and reliability.

Polyurethane bushings that resist compression and deformation offer unparalleled durability and performance across diverse industries. Their unique properties, including exceptional strength-to-weight ratio and resistance to chemicals and wear, make them a superior choice for applications demanding stability and longevity. By choosing polyurethane bushings, manufacturers can enhance equipment efficiency, reduce maintenance costs, and ensure safe, reliable operations in even the most demanding environments.