Polyurethane bushings are advanced automotive components made from high-performance materials that offer exceptional compression and deformation resistance. They are crucial for maintaining vehicle stability and performance in parts subject to constant vibration and pressure, such as muffler tips, suspension kits, exhaust components, and engine mounts. Beyond automotive, polyurethane bushings are indispensable across industries like manufacturing, construction, and machinery due to their durability and versatility, making them ideal for high-performance applications requiring robust performance and resistance to deformation.

Discover the remarkable world of polyurethane bushings, engineered materials that offer superior resistance against compression and deformation. This article explores the unique properties of these versatile components, highlighting why their robust design is crucial for various applications. From automotive suspensions to industrial machinery, polyurethane bushings provide enhanced durability and performance. Learn how their ability to withstand intense pressure and maintain shape makes them an indispensable choice for demanding environments.

- Understanding Polyurethane Bushings and Their Properties

- Why Compression and Deformation Resistance is Crucial

- Applications and Benefits of High-Resistance Polyurethane Bushings

Understanding Polyurethane Bushings and Their Properties

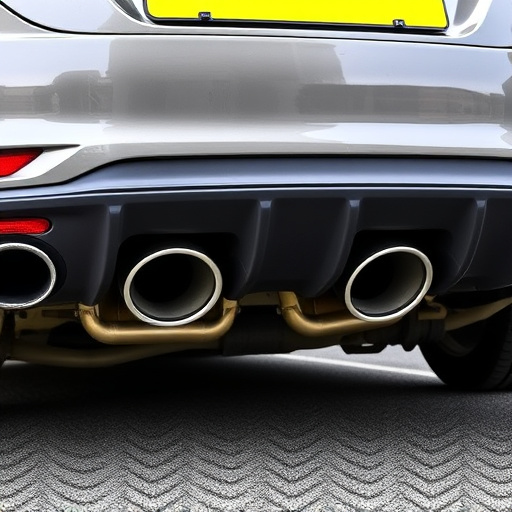

Polyurethane bushings are advanced components designed to withstand extreme conditions, making them a popular choice for automotive applications. These bushings are crafted from high-performance polyurethane materials that offer exceptional resistance to compression and deformation. This property is crucial when it comes to maintaining vehicle stability and performance, especially in parts like muffler tips, where constant vibration and pressure are common.

Their durability stems from the chemical composition of polyurethane, allowing it to retain its shape even under heavy loads. This makes them ideal for use in suspension kits, ensuring a smooth ride and precise handling. Unlike traditional bushings, polyurethane variants don’t deform or compress easily, providing long-lasting protection against wear and tear. Additionally, their versatility extends to various automotive systems, from exhaust components (like cat back exhaust) to engine mounts, ensuring optimal performance across different vehicle parts.

Why Compression and Deformation Resistance is Crucial

In the automotive industry, where precision and reliability are paramount, components like polyurethane bushings play a critical role in ensuring optimal vehicle performance. The ability to resist compression and deformation is a pivotal aspect of their design, as it directly impacts the overall functionality and longevity of various systems within a vehicle. Polyurethane bushings, known for their versatility and durability, offer exceptional resistance to these forces, making them indispensable in high-performance parts applications.

When installed in exhaust systems, for instance, these bushings must endure constant vibration, noise, and extreme temperatures without compromising integrity. Their compression resistance prevents unwanted compression of the exhaust components, ensuring efficient gas flow and maintaining vehicle performance. Similarly, deformation resistance is crucial to preserve the shape and alignment of bushings, especially under heavy loads or sudden impacts, thereby safeguarding the stability and safety of the entire mechanical setup.

Applications and Benefits of High-Resistance Polyurethane Bushings

Polyurethane bushings that resist compression and deformation find their way into a multitude of applications across various industries. From automotive to industrial machinery, these high-performance parts offer unparalleled durability and stability. In vehicles, for instance, they are integral in enhancing the performance and longevity of critical components like suspension systems, steering mechanisms, and brake components. Their ability to withstand extreme pressure without compromising shape makes them ideal for use with performance air filters, ensuring optimal airflow and engine efficiency.

Beyond automotive uses, high-resistance polyurethane bushings offer significant advantages in diverse sectors. In construction equipment, they absorb shock and reduce vibration, minimizing wear on moving parts. This translates into lower maintenance costs and increased machine lifespan. Similarly, in manufacturing settings, these bushings are employed to stabilize machinery, enhancing overall production efficiency. Their versatility, combined with superior material properties, makes them a go-to solution for any application demanding robust performance and resistance to deformation.

Polyurethane bushings that resist compression and deformation offer unparalleled performance in various applications, from automotive suspensions to industrial machinery. Their unique properties ensure longevity and stability under extreme conditions, making them a game-changer in many sectors. By understanding the importance of resistance to compression and deformation, professionals can leverage these high-performance bushings to enhance efficiency, reduce maintenance, and improve overall system integrity.