Polyurethane and rubber bushings serve complementary roles in automotive engineering. Polyurethane bushings are durable, rigid, and ideal for structural integrity in suspension systems, while rubber bushings offer flexibility, shock absorption, and noise reduction, making them perfect for brake rotors and suspension mounts. Polyurethane excels in high-performance vehicles and heavy-duty applications, providing better shock absorption and reducing road noise compared to traditional rubber bushings. Choosing the right polyurethane bushings enhances vehicle performance, improves fuel efficiency, and prolongs the lifespan of critical parts, offering a smoother, quieter ride for drivers.

“Enhance your vehicle’s performance with an in-depth look at rubber vs. polyurethane bushings. This article unravels the unique characteristics and applications of each material, offering a comprehensive comparison of their strengths and weaknesses. From durability to flexibility, discover how these bushing types impact vehicle dynamics. Learn the art of selecting the ideal bushing for optimal performance, ensuring your ride excels on the road. Explore the world of polyurethane bushings and unlock their potential for a smoother, more responsive driving experience.”

- Understanding Rubber and Polyurethane Bushings: Their Nature and Applications

- Performance Comparison: Strengths and Weaknesses of Each Material

- Choosing the Right Bushing Type for Optimal Vehicle Performance

Understanding Rubber and Polyurethane Bushings: Their Nature and Applications

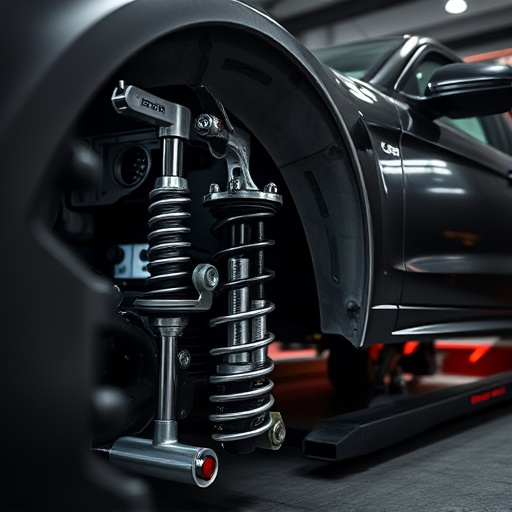

Rubber and polyurethane bushings are essential components in various automotive systems, each with distinct properties catering to different needs. Polyurethane bushings are known for their exceptional durability and rigidness, making them ideal for applications that demand high structural integrity. These bushings are often found in vehicle suspension systems, providing stable and controlled movement while reducing unwanted vibrations. Their versatility allows them to be utilized in a wide range of parts, from steering columns to exhaust muffler tips, ensuring optimal performance and longevity.

On the other hand, rubber bushings offer superior flexibility and shock absorption. Commonly used in applications like brake rotors and suspension mounts, rubber provides a buffer against sudden impacts and road irregularities. This flexibility makes them more adaptable to varying driving conditions, contributing to improved vehicle handling and comfort. While polyurethane may be stiffer, rubber’s give allows for better compliance, which can be crucial in certain high-performance scenarios where precise control and reduced noise are paramount.

Performance Comparison: Strengths and Weaknesses of Each Material

Rubber and polyurethane bushings each bring unique attributes to automotive applications, from engine mounts to exhaust mufflers and brake pad components. In terms of performance, polyurethane bushings stand out for their exceptional strength-to-weight ratio and rigid structure, making them ideal for high-performance vehicles where minimizing flex and maintaining precision alignment are paramount. They offer superior load-bearing capacity compared to rubber, proving especially useful in heavy-duty applications like truck suspensions and race car setups.

However, while polyurethane bushings excel in rigidity and durability, they may not match the shock absorption and noise reduction qualities of rubber. Rubber components have long been trusted for their ability to dampen vibrations and isolate noise, making them preferable for passenger comfort in daily drivers and providing a softer ride when compared to rigid polyurethane options. When it comes to exhaust tips and mufflers, rubber bushings can help absorb resonance and vibrational energy, ensuring a quieter driving experience.

Choosing the Right Bushing Type for Optimal Vehicle Performance

Choosing the right bushing type is crucial for achieving optimal vehicle performance. Polyurethane bushings, for instance, offer exceptional durability and resistance to wear and tear, making them a preferred choice for those seeking long-lasting performance enhancements. Their ability to maintain their shape over time ensures smooth operation of various components, such as cold air intakes and exhaust mufflers, resulting in improved engine response and overall vehicle handling.

Compared to traditional rubber bushings, polyurethane provides better shock absorption and reduces road noise, providing a smoother ride. This makes it an ideal upgrade for vehicles designed for performance, including those with custom performance exhaust systems. By selecting the appropriate bushing type, drivers can enhance their driving experience, improve fuel efficiency, and extend the lifespan of critical vehicle parts like suspension components and drivetrain elements.

When it comes to vehicle performance, choosing the right bushing type is crucial. Both rubber and polyurethane bushings offer unique advantages and applications. Polyurethane bushings excel in durability and load-bearing capacities, making them ideal for high-performance vehicles and off-road adventures. On the other hand, rubber bushings provide excellent shock absorption and noise reduction, enhancing passenger comfort. Understanding these materials allows car enthusiasts to make informed decisions, ensuring optimal vehicle performance tailored to their needs. So, whether you’re seeking a smooth ride or superior durability, selecting the appropriate bushing type is key to achieving peak automotive performance.