Polyurethane bushings offer superior durability and stiffness for high-stress automotive applications like exhaust systems, while rubber excels at shock absorption and flexibility in complex suspension setups. Modern polyurethane formulations bridge this gap, making them versatile for various systems requiring vibration control and structural integrity maintenance. For enhanced performance and comfort, polyurethane bushings are ideal for vehicle suspension and brakes; rubber is preferred for softer, compressible shock absorption.

“In the pursuit of optimal vehicle performance, understanding the nuances between rubber and polyurethane bushings is paramount. This article delves into the distinctive properties of these suspension components, focusing on polyurethane bushings, their rising popularity, and how they compare to traditional rubber. We explore key factors like durability, flexibility, and applications, guiding readers in selecting the best bushing type for enhanced vehicle performance.”

- Understanding Rubber and Polyurethane Bushings

- Performance Comparison: Durability and Flexibility

- Application and Choosing the Right Bushing Type

Understanding Rubber and Polyurethane Bushings

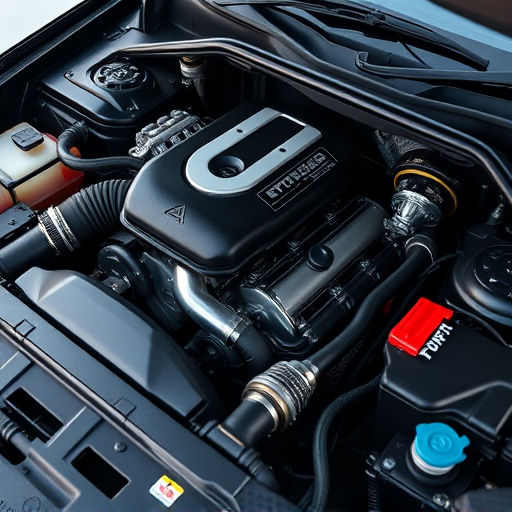

Rubber and polyurethane bushings are essential components in various automotive applications, particularly when it comes to enhancing vehicle performance. These bushings serve as connectors between metal parts, ensuring smooth movement and reducing vibrations. Understanding their unique characteristics is crucial for selecting the right high-performance parts, especially for those interested in optimizing their vehicle’s exhaust mufflers.

Polyurethane bushings have gained popularity due to their exceptional durability and ability to withstand extreme conditions. They offer a stiffer structure than traditional rubber, making them ideal for performance exhaust systems that experience high levels of stress. In contrast, rubber bushings are known for their flexibility and shock absorption properties, which can be advantageous in vehicles with complex suspension setups, ensuring a smoother ride without compromising structural integrity.

Performance Comparison: Durability and Flexibility

When comparing rubber to polyurethane bushings, one key area to consider is durability and flexibility. Polyurethane bushings offer superior durability compared to traditional rubber options, especially in high-stress applications like intake components and brake components. This enhanced durability stems from polyurethane’s rigid cellular structure, which provides excellent resistance against compression and shear forces.

In terms of flexibility, rubber typically outperforms polyurethane. However, modern polyurethane formulations have made significant strides, offering a balance between durability and flexibility. This makes polyurethane bushings suitable for applications that demand both robust performance and some degree of compliance, such as absorbing vibrations while maintaining structural integrity.

Application and Choosing the Right Bushing Type

When it comes to applications requiring enhanced durability and flexibility, polyurethane bushings stand out as a preferred choice. Their versatile nature allows them to be integrated into various systems, from vehicle suspension to air intake and brake components. The selection of the right bushing type is crucial for optimal performance. For instance, in high-performance vehicles, polyurethane bushings can significantly improve handling and ride quality by absorbing road vibrations, thereby enhancing driver comfort and safety.

Choosing between rubber and polyurethane depends on specific requirements. Polyurethane offers superior resistance to wear and tear, making it ideal for harsh conditions or components that demand extended service life. In contrast, rubber may be a better fit for applications where a softer, more compressible material is needed to manage shock absorption efficiently. For performance brakes, for instance, polyurethane bushings can contribute to improved braking efficiency by reducing the transfer of road noise and vibrations to the vehicle’s interior.

When comparing rubber to polyurethane bushings, the choice ultimately depends on your specific application needs. Polyurethane offers enhanced durability and flexibility, making it ideal for high-performance and dynamic applications. Rubber, however, maintains its versatility in various conditions, ensuring a reliable choice for many automotive and industrial uses. For optimal performance, understanding these material differences is key to selecting the best bushing type for your requirements.